EPFL, Empa and CSEM develop the first fully compostable smart sensor

2 December 2025

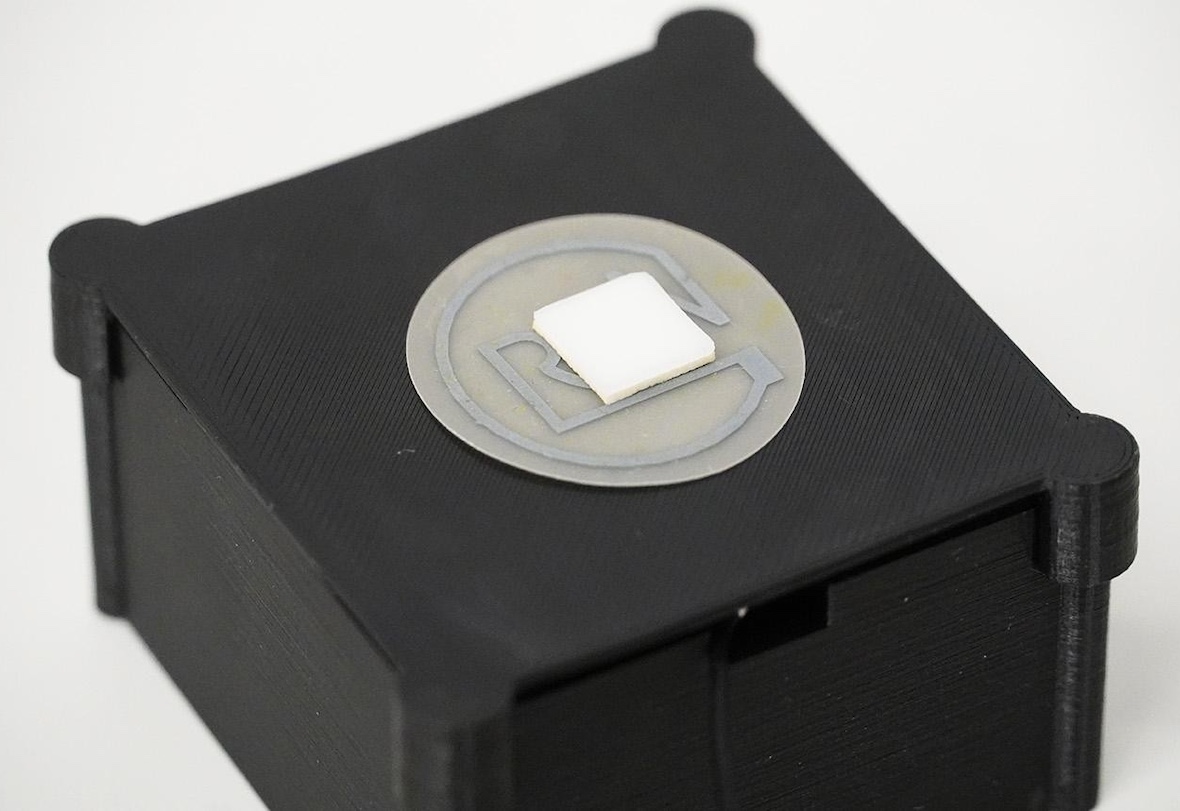

A fully compostable temperature-sensing tag developed by EPFL, Empa and CSEM detects when a shipment has exceeded a critical threshold. | © EPFL / LMTS 2025

A fully compostable temperature-sensing tag developed by EPFL, Empa and CSEM detects when a shipment has exceeded a critical threshold. | © EPFL / LMTS 2025

Researchers from Western Switzerland have unveiled the first fully compostable smart sensor to monitor temperature-sensitive goods, offering a sustainable alternative to conventional tags.

Researchers from EPFL, Empa and CSEM have developed the world’s first fully compostable smart sensing tag designed to monitor temperature-sensitive shipments such as vaccines, medicines and food products. The breakthrough offers a sustainable alternative to conventional silicon-based sensors used in logistics and cold-chain supply management.

Global supply chains increasingly rely on environmental monitoring to ensure that fragile goods remain within strict temperature ranges during transport. However, equipping each package with traditional electronic tags remains costly and generates substantial electronic waste. In response, the three Swiss research institutions joined forces through GREENsPACK, a four-year project funded by the Swiss National Science Foundation (SNSF) and Innosuisse under the BRIDGE Discovery program, to develop a fully biodegradable device capable of wireless temperature monitoring.

The resulting tag is a lightweight, printed, chipless sensor made entirely from biodegradable materials. The team fabricated the device on a composite substrate of biopolymer and cellulose fibers developed at Empa, combined with circuit and readout technologies engineered by CSEM. Instead of silicon chips or batteries, the tag uses a wireless electrical resonator built from highly conductive zinc tracks protected by natural wax.

When scanned with a wireless tag reader, the sensor generates a resonance signal that encodes its status. If the shipment exceeds a predefined temperature threshold, a bio-based oil integrated into the tag melts, altering the resonance frequency. The change is irreversible, enabling logistics operators to immediately determine whether a product was exposed to unsafe conditions. Different temperature thresholds can be selected by using oils with specific melting points, such as frozen olive, jojoba or coconut oil.

According to EPFL’s Soft Transducers Laboratory (LMTS), which led the device’s development, the technology demonstrates how smart sensing can be aligned with environmental sustainability. In 2022, global e-waste reached 62 megatons, with only 22 percent recycled, highlighting the need for alternatives to conventional electronics. By integrating compostable materials, additive manufacturing and chipless design, the GREENsPACK platform seeks to reduce environmental impact while supporting more sustainable logistics and Internet-of-Things applications.