Fribourg, Switzerland’s hub for digital manufacturing

The Marly Innovation Center in Fribourg brings together cutting-edge research institutes and industrial partners driving the future of digital manufacturing. | © Marly Innovation Center

The Marly Innovation Center in Fribourg brings together cutting-edge research institutes and industrial partners driving the future of digital manufacturing. | © Marly Innovation Center

A world-class ecosystem where research, education, and industry converge to shape the future of sustainable production.

The canton of Fribourg has established itself as a center of excellence in digital manufacturing, driven by iPrint, one of the world’s leading institutes for inkjet-based production technologies.

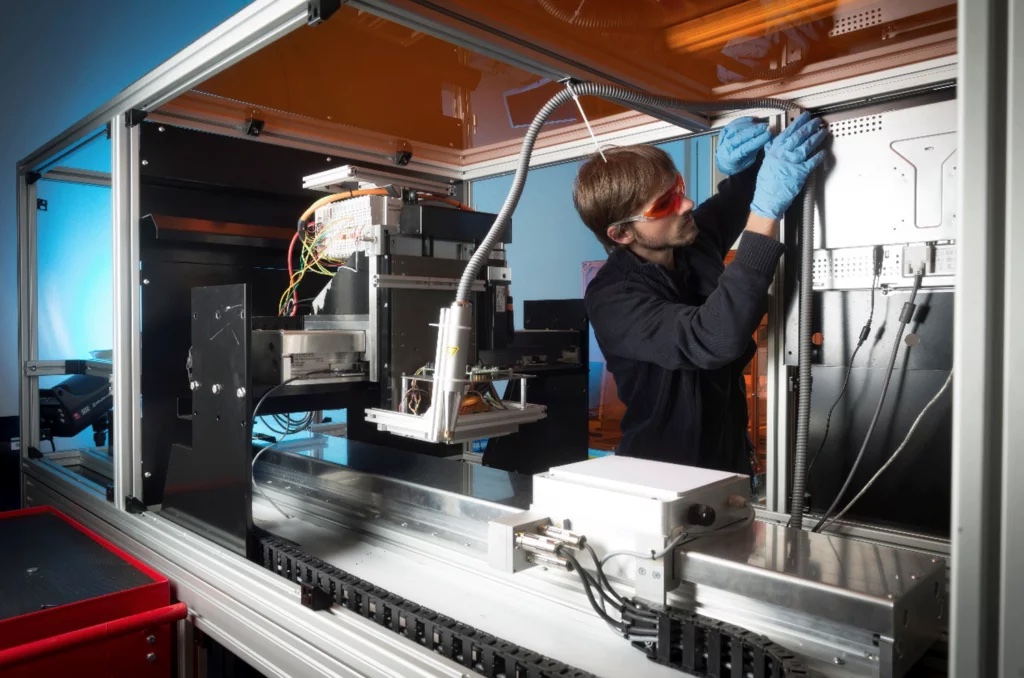

Located at the Marly Innovation Center (MIC), iPrint brings together cutting-edge research, industrial collaboration, and world-class training to reinvent how products are designed and manufactured.

As part of the School of Engineering and Architecture of Fribourg (HEIA-FR) within the University of Applied Sciences and Arts Western Switzerland (HES-SO), iPrint stands at the intersection of science, industry, and education. Fribourg itself, a dynamic university town bridging the French- and German-speaking regions of Switzerland, provides the ideal environment for innovation and collaboration.

Why inkjet, why now?

In an era where traditional manufacturing can be costly, rigid, and environmentally harmful, digital production by inkjet printing offers a more flexible and sustainable alternative. This technology enables :

- Rapid prototyping and faster time-to-market

- Mass customization with minimal waste

- Additive and functionalized manufacturing (2D, 2.5D, 3D, or even 4D)

- Fully automated processes aligned with Industry 4.0 principles

From ceramics and packaging to watchmaking, biomedicine, pharmaceuticals, automotive, aerospace, and even food, inkjet is redefining production possibilities across industries.

iPrint: From research to real-world impact

Founded in 2013, iPrint has grown into a globally recognized competence center with over CHF 3 million in annual turnover. Its multidisciplinary team of researchers, engineers, and technicians masters every stage of the inkjet process, from ink formulation and drop visualization to surface treatment, printhead design, and advanced materials.

This expertise allows industry partners to move rapidly from concept to scalable production. Global players such as Epson Europe B.V. and Markem-Imaje have even established branches at MIC to collaborate directly with iPrint, while Polytype, Konica-Minolta, and Kyocera Europe GmbH partner through shared laboratory facilities.

Education, training, and knowledge exchange

Beyond research, iPrint serves as a global education hub for inkjet technologies. Its Inkjet Training Center offers foundation and masterclass programs that blend theory with practical lab experience. Over 300 professionals from more than 150 companies in 25 countries have already benefited from this training.

In 2024, iPrint also co-founded the Advanced Inkjet Technology Conference with IS&T, held biennially in Fribourg. The next edition will take place from January 26–28, 2026, continuing to foster dialogue between academic researchers and industrial leaders.

A thriving innovation ecosystem

The Marly Innovation Center is home not only to iPrint but also to a vibrant network of companies active in inkjet, additive manufacturing, and advanced materials. The region’s innovation ecosystem includes global leaders such as Bobst, 3D Systems and Epson, as well as promising local spin-offs like Droptimize and Seprify.

Fribourg’s innovation landscape is further reinforced by HEIA-FR’s research institutes in chemistry, AI, plastics, mechatronics, and safe systems, alongside close partnerships with the University of Fribourg and the EPFL.

Where innovation meets industry

“We’re not just a research institute. We’re a partner, a place where ideas turn into prototypes, and prototypes into scalable production,” says Dr. Gioele Balestra, Co-Head of iPrint.

With its multidisciplinary team, advanced technical infrastructure, and flexible collaboration models, iPrint offers tailor-made solutions for feasibility studies, process optimization, and joint research, from short-term projects to multi-year industrial collaborations.

A bridge between research and industry

From its roots in Fribourg’s long printing tradition to its leadership in next-generation manufacturing, iPrint embodies Swiss innovation at its most practical and collaborative.

By combining sustainability, digital precision, and industrial relevance, the region continues to position itself as a European benchmark for digital production.